Superfinish

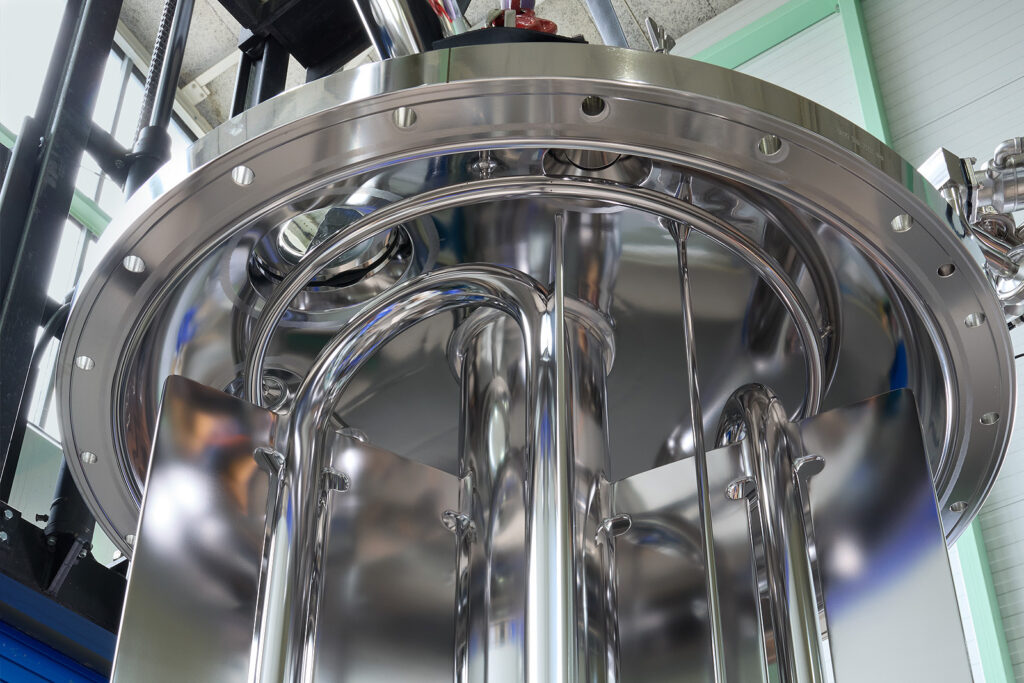

Perfect Stainless-Steel Surfaces for the Pharmaceutical and Biotech Industries

In the pharmaceutical and biotechnology industries, the quality of product-contact stainless-steel surfaces, particularly in the area of weld seams, is a critical quality factor. Surface condition plays a decisive role in ensuring product safety, compliance with stringent hygiene requirements, and the integrity and cleanability of complex product-contact components. Insufficiently processed surfaces can significantly increase the risk of microbial contamination, limited cleanability, and partial impurities, all of which pose a threat to the entire manufacturing process.

With MAURER® Superfinish, we guarantee technically flawless product-contact surfaces with Ra values of up to ≤ 0.10 µm, meeting the highest standards of the pharmaceutical industry regarding hygiene, corrosion resistance, and cleanability.

Evaluation of Stainless-Steel and Weld Seam Surfaces in Product-Contact Areas

In practice, stainless-steel and weld seam surfaces in product-contact areas are often specified only by a maximum allowable roughness value (e.g., Ra ≤ 0.40 µm). However, this purely quantitative specification is insufficient to ensure full compliance with hygienic and regulatory requirements.

Expert Assessment

Although the Ra-value provides a quantitative measure of surface roughness, it offers only limited insight into the technical and hygienic suitability of the surface, particularly regarding weld seams. To ensure consistently high surface quality, additional criteria concerning the processing method and grinding procedure must be considered. The following aspects are essential:

1. Grinding Methodology

The quality of the surface is largely determined by the grinding technique applied.

2. Defined Grinding Process

A controlled, step-by-step grinding process that progressively refines the surface structure is required.

3. Proper Weld Seam Grinding

Professional grinding of weld seams in product-contact areas is crucial for meeting hygienic and regulatory requirements.

4. Appropriate Abrasives for Stainless Steel

For processing stainless steel grades such as 1.4404 (AISI 316L) or comparable austenitic materials, only abrasives specifically recommended for this purpose should be used.

5. Electropolished Surface

A technically flawless electropolished surface can only be achieved if the preceding grinding work has been carried out carefully and professionally. If the grinding process is not properly executed, any defects will become clearly visible after electropolishing and will compromise the surface quality. Therefore, precise surface preparation is the key to achieving an ideal electropolished finish that also meets the pharmaceutical industry’s stringent requirements for hygiene, corrosion resistance, and cleanability.

Rely on MAURER® Superfinish – for Exceptional Surface Quality and True Process Reliability. Further information and technical details can be found in the MAURER® Superfinish Factsheet PDF.